First, we run our iron-rich regional clay through a pug machine to squeeze out air bubbles. It’s then carefully measured into precise little lumps, and pressed into a plaster mold. The Mug is formed by a metal profile blade that pushes the clay to the outside of the mold while the mold spins. This crucial step ensures each vessel's overall consistency and strength. Once in the mold, The Mug body is formed on the vertical pull-down jigger and dried overnight. For demonstration purposes, the mold has been cut in half after forming to show a cross-section of the formed mug inside the mold.

In the morning, when our baby Mug is still wet, but not as easily dimpled or dinged, we pop it out. Scrappy and unfinessed, these new Mugs now need the soft touch of a skilled hand. Using trimming wires, hooks, and hand tools, we polish off the edges and crevices to get them looking smooth and refined. It’s this pre-step that really preps the Mugs for successful glaze application.

This fresh, greenware body is now primed and ready for next steps, like attaching the perfect handle. At this stage, we fire up the ram press, which uses hydraulic pressure and a "die" to press out smooth and strong handles; three at a time. Once formed, we stick them in a box and let them reach a dryness equivalent to the body for seamless affixing. For a strong bond, we score the body and the handle where they will meet in an everlasting union.

After the handle is affixed, each pot made at East Fork gets stamped on the bottom with our maker's mark. We use brass or plastic stamps to lovingly press each one by hand. Once they're stamped, they'll dry out on the racks a bit more before they get stacked into a low-fire bisque kiln, prior to being glazed.

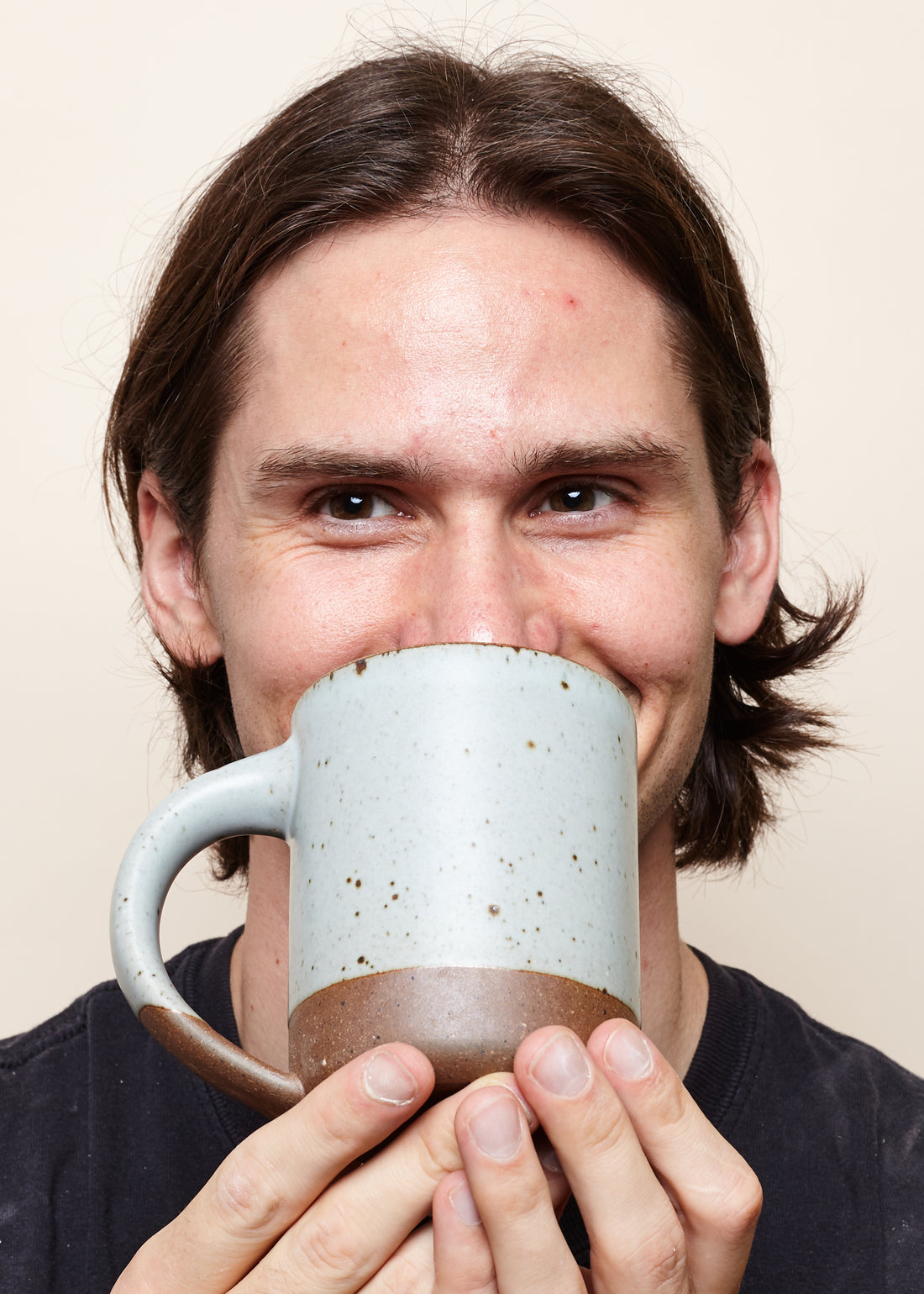

The bottom of our Mug is unglazed, a space just big enough for an index finger and thumb to grip. We hand dip each Mug in its proper glaze bucket, and then wipe off the lip with a sponge for that signature, raw clay rim. We sand the rim down until it's super smooth—and with use, that lip keeps getting softer and softer.

After all that prepping, pressing, assembling, cleaning, bisquing, and glazing, it's time for the last firing in our high temperature kiln. Not only does this step create a chemical reaction, binding the glaze to the porous clay, but it produces the strong, chip-resistant vessel you know and love. Every carefully considered Mug gets sanded for smooth edges and inspected before making its way to live happily ever after in your kitchen cupboard.